Our services cover a wide range of components, including corrugating rolls, pressure rolls, glue rolls, doctor rolls, and cassette units. With a combination of standardized processes and custom repair techniques, we restore the performance of worn or damaged rolls, extend their working life, and help reduce unexpected downtime. Each project is handled with precision to ensure that refurbished components meet the same performance and reliability standards as new equipment.

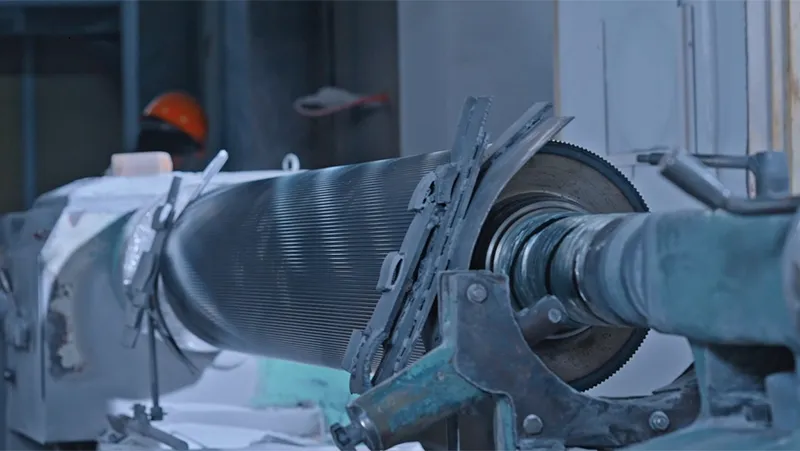

Our repair and refurbishment services for corrugating rolls are tailored to restore both performance and precision, whether the rolls are tungsten carbide coated or chrome plated. Each project follows a detailed, multi-stage process to ensure durability, dimensional accuracy, and extended roll life.

- Disassembly of Components

Complete removal of related parts such as bearing housings, sleeves, and oil seals for full access and inspection. - Comprehensive Technical Assessment

We measure hardness, wear levels, flute height and pitch, diameter tolerances, and surface condition using calibrated instruments. - Digital Inspection Report & Repair Plan

A detailed report is provided, along with a tailored restoration plan based on the roll’s current condition. - Specialized Repair Procedures

Tungsten Carbide Rolls: Carbide layer removal → precision grinding → sandblasting → thermal spraying → polishing

Chrome-Plated Rolls: Precision weld repair → precision grinding → hard chrome electroplating → surface thickness control - Three-Stage Quality Control

Inspections are performed after during and after grinding, after coating, and before final delivery. In addition, test runs with paper simulate actual production conditions to verify performance.

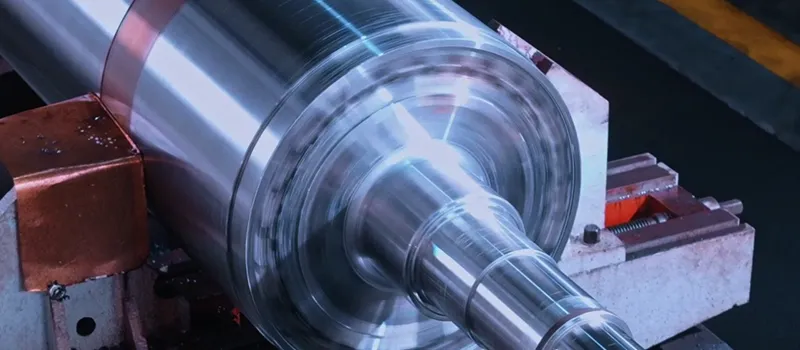

Our pressure roll repair and refurbishing process focuses on restoring mechanical balance and surface accuracy to ensure stable performance under high-speed conditions. We achieve this through two main steps:

- Dynamic balancing to eliminate vibration and ensure smooth, stable operation

- Precision cylindrical grinding to restore surface finish and maintain dimensional accuracy

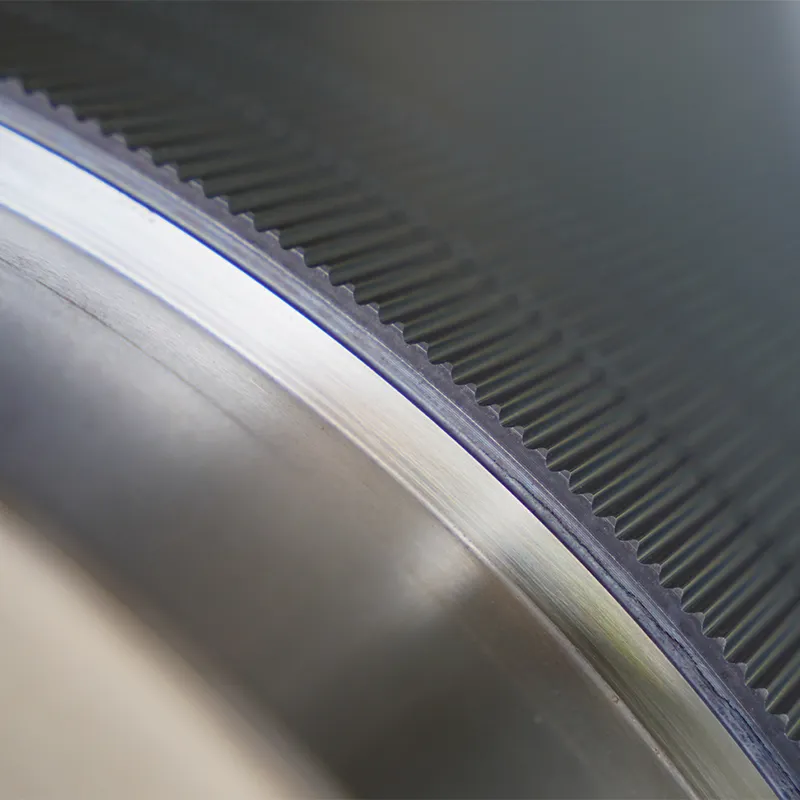

- To restore glue rolls to optimal working conditions, we remove worn or damaged engraving using precision machining and reapply new patterns through CNC-controlled embossing. This process ensures uniform cell structure and accurate glue application during production.

- Once re-engraved, the roll surface undergoes a hard chrome plating treatment, which reinforces durability and protects against wear, corrosion, and adhesive buildup.

- We provide precision refurbishment services for doctor rolls used in corrugated board production. The roll surface is carefully reground using high-precision cylindrical grinding to restore roundness and surface quality.

- To enhance durability and resistance to adhesive and solvent exposure, the roll is then treated with a hard chrome coating, extending its service life and maintaining smooth, consistent glue regulation during operation.

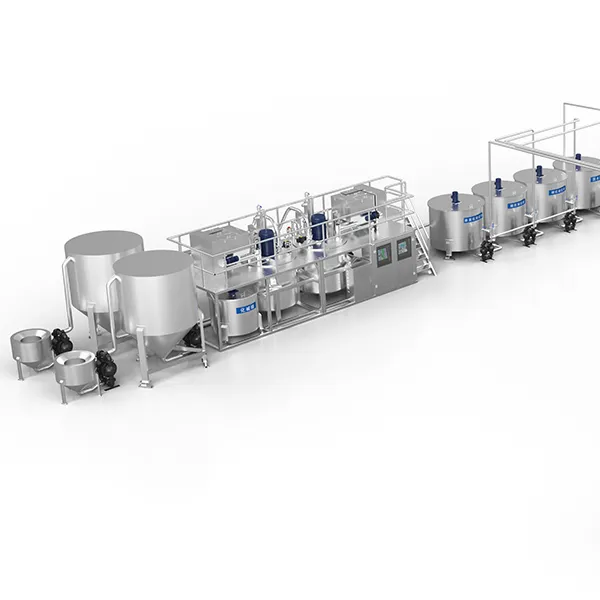

- Our refurbishing services for corrugator cassettes are designed to restore the performance and structural alignment of corrugator cassettes used in single facer modules. We carry out: - Hydraulic cylinder assembly replacement for stable pressure control

- Precision calibration of positioning rails to correct misalignments

- Dynamic leveling compensation to maintain balance during high-speed operation - Our repair process is fully traceable, with detailed records kept at every stage. We also offer optional before-and-after analysis reports. Each project is backed by a 12-month quality guarantee to ensure long-term reliability and peace of mind.

- Working with Yonghui means gaining measurable value: cassette refurbishment typically costs only 50–60% of a new unit, while lead times are reduced by up to 50% compared to industry averages. With more than 1,000 verified cases in our process database, we deliver proven results backed by over 20 years of experience in industrial roll and cassette services.

- Let our team help extend the service life of your equipment with efficient, data-driven repair solutions tailored to your production needs.