Corrugated Board Machinery

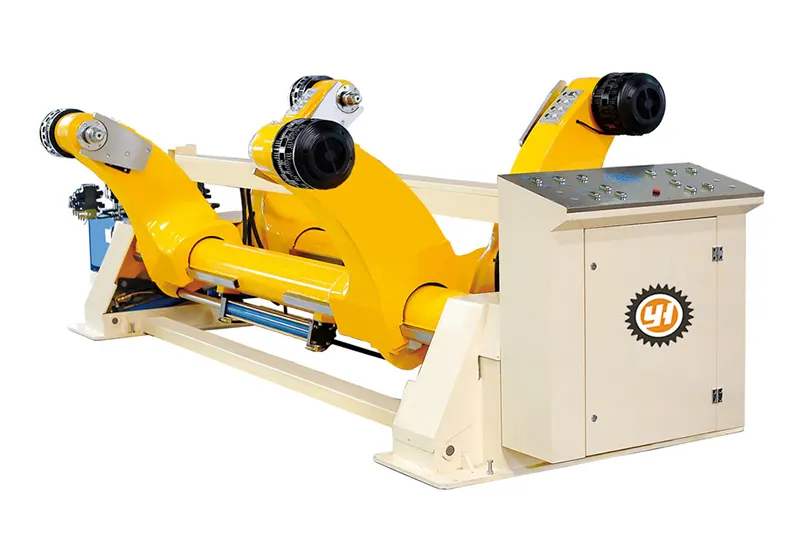

Roll Stand

Used in corrugated cardboard production line for holding and feeding paper rolls

Corrugated Board Machinery

Roll Stand

Used in corrugated cardboard production line for holding and feeding paper rolls

- Fully hydraulic roll stand designed to hold paper rolls with a maximum diameter of 1500 mm

- Standard configuration includes a multi-point braking system and internal expandable chuck

- Equipped with Taiwan-sourced hydraulic cylinders and 5.5 kW hydraulic station motor

- Electrical components supplied by Schneider Electric (France)

- Pneumatic system components provided by AIRTAC

In corrugated board production, the roll stand serves as the entry point for paper feeding, holding rolls firmly in place while ensuring steady unwinding during operation. To maintain structural integrity under continuous load, roll stands adopt a dual-cylinder synchronized lifting design, which helps distribute pressure evenly and reduces the risk of shaft or arm distortion. Durability is reinforced by the use of directional bearings and hardened steel locking sleeves that are easy to replace. The equipment incorporates a Taiwan hydraulic system, FRA Schneider electrical components, and AIRTAC pneumatic parts, ensuring smooth and consistent performance under high-demand conditions. With a maximum clamping diameter of 1500 mm, the roll stand supports a wide range of roll sizes. Its multi-point braking system and expandable chuck design simplify roll changeovers and provide stable paper feeding, which helps reduce waste and keeps production running efficiently.

- The hydraulic base includes directional bearings that help absorb stress from uneven ground settling, protecting the hydraulic cylinders from damage over time.

- Lifting arm locking points are reinforced with bearing-grade steel sleeves, improving durability and allowing for easier part replacement.

- The dual-cylinder lifting system on both the left and right sides ensures synchronized movement and long-term operational stability.

- Traditional roll stands often rely on a single hydraulic cylinder to raise one arm, which can lead to imbalanced force, bending, and poor tension control during extended use. Our roll stand uses cylinders on both sides of the main shaft, distributing pressure evenly. This helps maintain shaft alignment, prevents deflection, and improves feeding stability, especially when handling wide-format rolls.