Corrugated Board Machinery

Automatic Splicer

Applied in conjunction with corrugator roll stand to automatically join two paper rolls for continuous operation and enhanced productivity

Corrugated Board Machinery

Automatic Splicer

Applied in conjunction with corrugator roll stand to automatically join two paper rolls for continuous operation and enhanced productivity

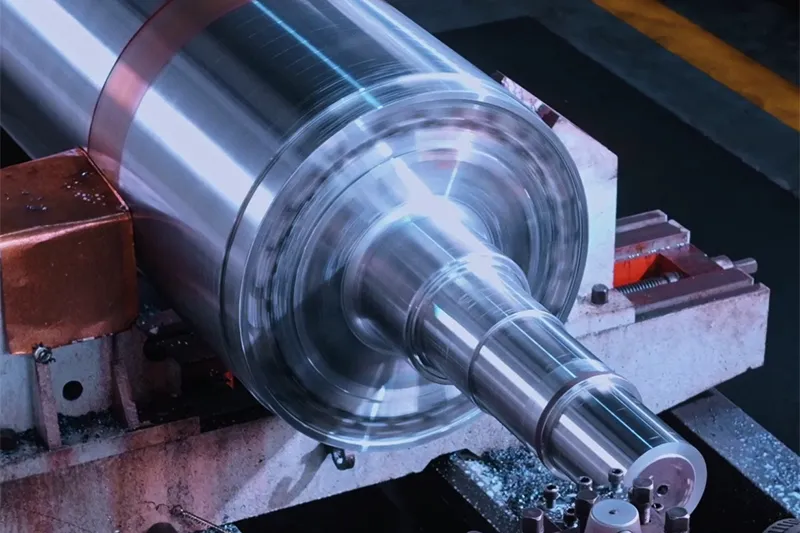

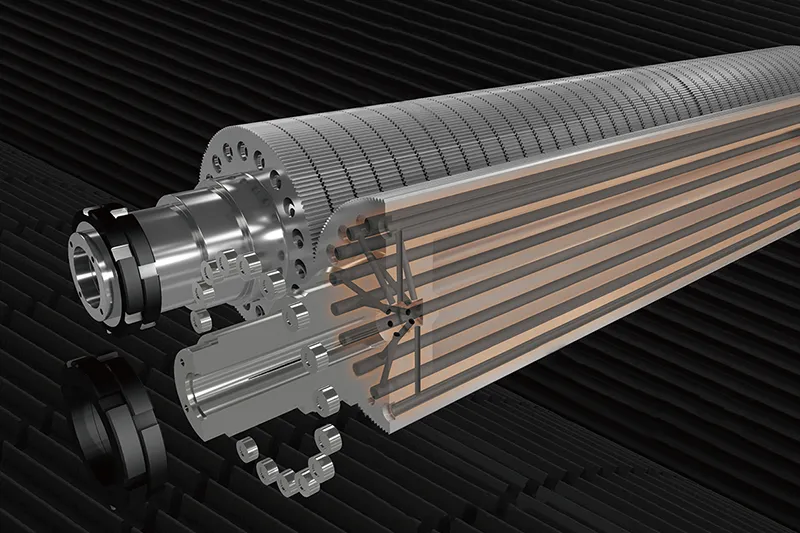

The automatic splicer is mainly used for seamless paper roll transitions in corrugated board production. Splicers automatically join the end of an expiring roll with the beginning of a new roll, eliminating downtime and enhancing continuous operation. Unlike traditional manual splicing, an automatic splicer ensures a smooth and efficient connection that minimizes interruptions. Comprising a splicing unit, roll stand, and control system, the automatic splicer delivers exceptional precision. The roll stand securely holds the paper rolls in place, while the splicing mechanism efficiently cuts and joins the rolls, ensuring a tight and secure splice without the risk of misalignment. With its robust engineering and enhanced reliability, the automatic splicer optimizes workflow and minimizes downtime, allowing manufacturers to focus on improving efficiency and output.

- High-speed paper splicing for seamless operation

- Ultra-short tail joints, only 4 cm, minimizing waste and ensuring a smooth, tight connection

- Reduced paper waste and increased production efficiency

- Smooth and consistent splicing with minimal downtime for improved workflow