Corrugated Board Machinery

Pre-Heater

Designed for preheating paper rolls to reach the desired process temperatures for optimal bonding of corrugated board

Corrugated Board Machinery

Pre-Heater

Designed for preheating paper rolls to reach the desired process temperatures for optimal bonding of corrugated board

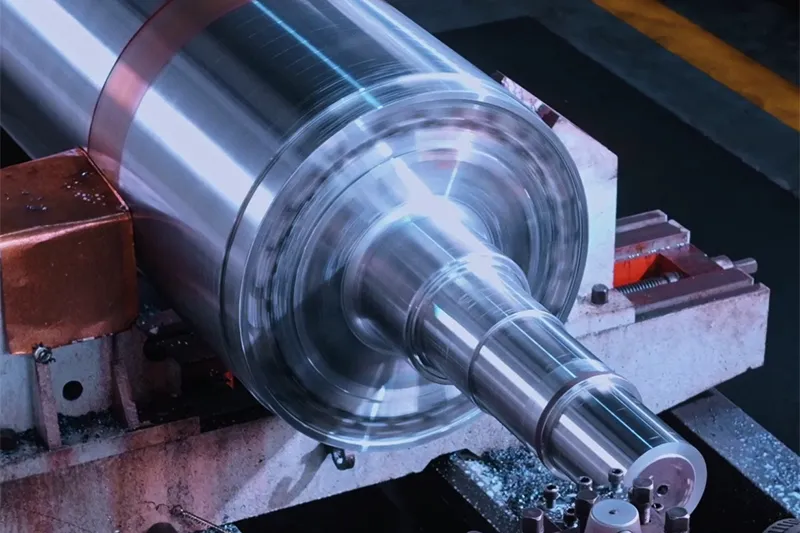

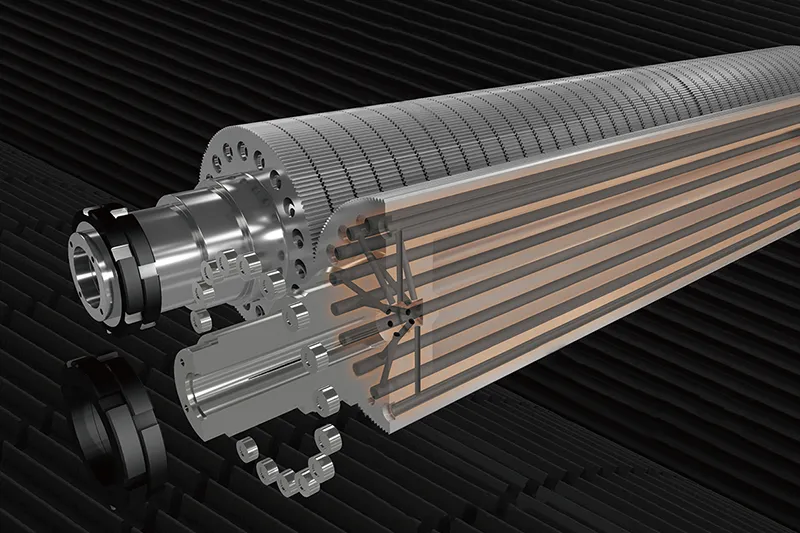

Optimizing the production process begins with the pre-heater which is designed to ensure that paper rolls are heated evenly before entering the corrugation process. By preheating the paper to the ideal temperature, the pre-heater improves the bonding between the medium and linerboard, resulting in stronger and more durable corrugated board. Our pre-heaters feature a large diameter heated cylinder (Ø1100mm/1000mm), coupled with advanced surface coating and dynamic balancing techniques. This ensures the cylinder rotates smoothly, evenly distributing heat across the surface and protecting the paper’s fiber structure from damage. The outcome is improved compressive strength, greater efficiency, and increased production speeds, enabling manufacturers to achieve higher throughput. By enhancing the paper’s quality and ensuring precise heat control, the pre-heater helps maintain consistent production, reducing defects and improving overall productivity in corrugated board production.

- The pre-heater features a large cylinder diameter (Ø1100mm/1000mm), providing optimal preheating for paper rolls and ensuring uniform temperature distribution.

- Electroplated surface treatment minimizes friction, allowing for smoother operation while maintaining even heat application, protecting the paper fiber structure.

- Uses a tensioned chain drive with a wrap angle exceeding 320°, ensuring better stability and reduced paper distortion at high speeds.

- Unlike traditional gear-driven systems, this design prevents wobbling and tension imbalances, which can lead to defects like inconsistent paper tension, noise, and wasted material.

- The pressure vessel certification guarantees the reliability and safety of the pre-heater in various operational environments.

- The automatic wrap angle adjustment, powered by a servo motor, provides precise control and adaptability to different production conditions and paper types.

- Variable speed rotation enables the pre-heater to adapt to production line speeds, enhancing energy efficiency and optimizing overall performance.

- With dynamic balancing, the pre-heater reduces vibrations, ensuring stable and smooth operation even under high-speed conditions.

- Peripheral heating eliminates the need for siphon pipes, reducing energy consumption and offering a more sustainable design with lower maintenance requirements.

- The steam and drive systems are separated for easier maintenance, and the design ensures practical and aesthetic appeal.