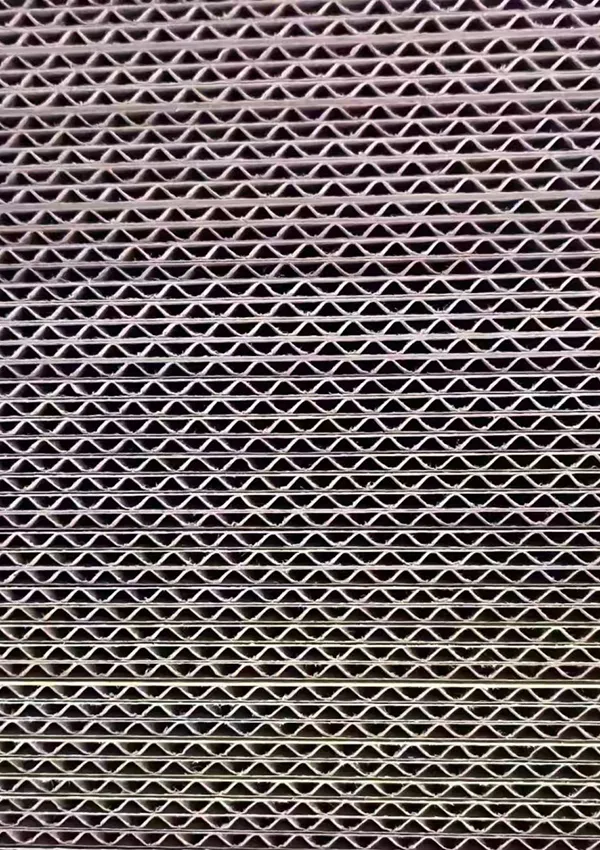

A corrugated packaging plant in Russia, specializing in the production of 5-ply corrugated board and cartons, was experiencing limitations in production speed. Their maximum machine speed was capped at 180 m/min. Any attempt to exceed this speed led to machine resonance, paper breakage, and poor board quality.

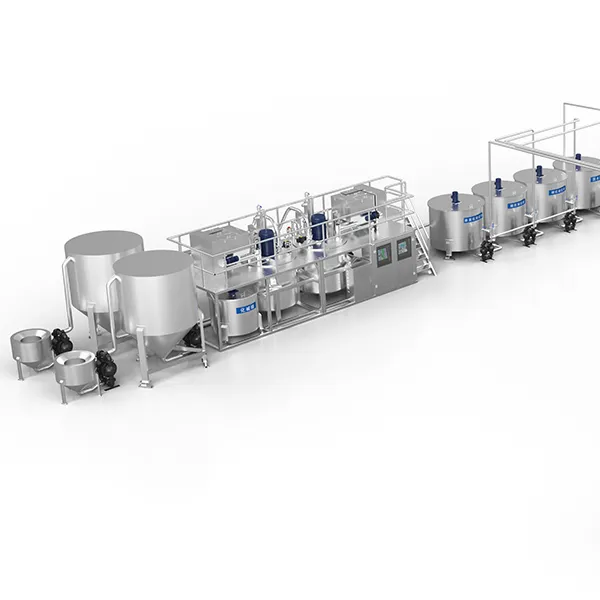

Yonghui conducted a comprehensive assessment of the client’s order structure and analyzed the existing flute profiles in use. Based on these insights, we re-engineered the flute profile and applied precise control over the corrugating roll’s raw material selection and machining accuracy. After installing the optimized corrugating rolls, the plant’s average running speed increased to 300 m/min. This significant improvement not only boosted overall production efficiency but also ensured that the quality of the corrugated board fully met the client’s performance requirements.