Corrugated Board Machinery

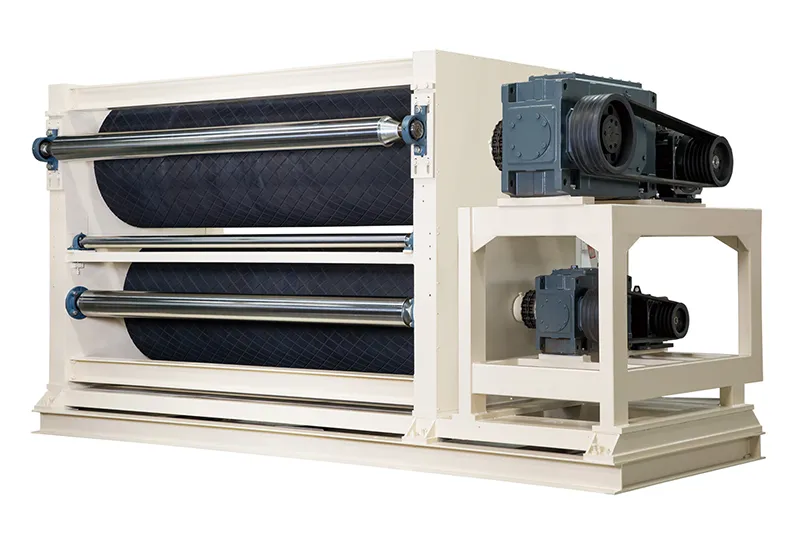

Drive Roll Stand

Adoption of up and down independent motor drive for stable and efficient operation of corrugated board production

Corrugated Board Machinery

Drive Roll Stand

Adoption of up and down independent motor drive for stable and efficient operation of corrugated board production

- The diameter of the upper and lower glue rollers is Ø910mm (with additional anti-slip rubber coating).

- Equipped with high-precision, servo motors and drives from the Italian brand Phase to ensure efficient operation.

Drive roll stands are a critical component of the corrugated board production line, functioning as the primary driving system. These stands feature a dual independent motor drive for both the upper and lower rollers, paired with a high-efficiency, toothless gearbox that ensures smooth operation. Compared to traditional gearbox designs, this system delivers up to 20% energy savings. Our drive roll stands are equipped with high-precision, servo motors and drives from the Italian brand Phase, guaranteeing stable and efficient power output for high-speed production. Our drive roll stands not only enhance the performance and longevity of the corrugated board production line but also contributes to improved energy efficiency and cost-effectiveness.

- The drive roll stand features independent motor drives for both the upper and lower rollers, coupled with an efficient toothless gearbox. This combination ensures smoother operation and results in up to 20% energy savings compared to conventional gearbox designs.

- Unlike traditional systems where both the upper and lower fabric belts need replacement, this this drive roll stand allows for the cost-effective replacement of just the upper belt. By using independent motor drives and adjusting speeds via the frequency converter, synchronization is maintained, reducing maintenance costs.

- Designed for quick stops, the drive roll stand can bring the system to a complete halt in just two seconds at 120m/min. This rapid stopping capability helps minimize paper waste, reduce downtime, and enhance energy efficiency throughout the production process.

- Our specialized guide roller design prevents slipping due to wear and tear. It allows for easy adjustment, increasing the friction between the fabric belt and the glue roller, ensuring the belt's longevity and stable performance at high speeds.

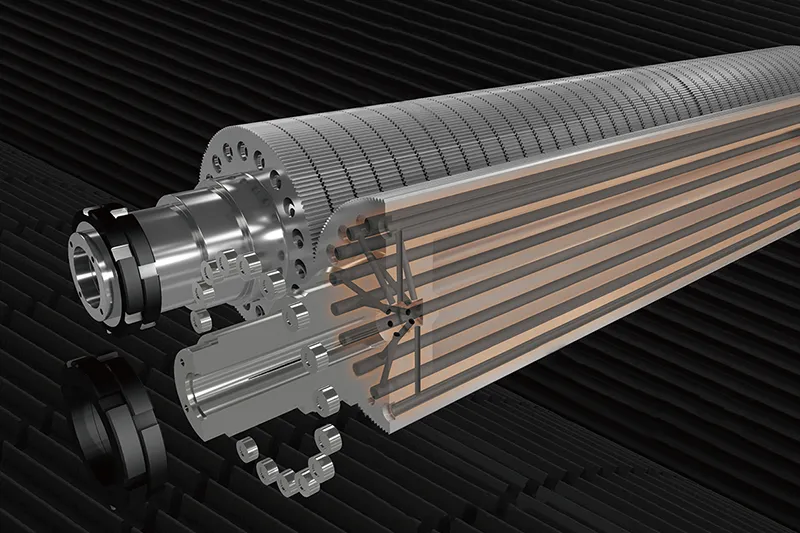

- The gearbox is equipped with an independent oil pump and copper tubes that efficiently distribute cooling fluid to each bearing and gear position. This innovative cooling system ensures optimal performance, reducing the risk of overheating and extending the gearbox’s lifespan.