Our team is ready to help you find the right rolls, equipment and solutions for your corrugated board production

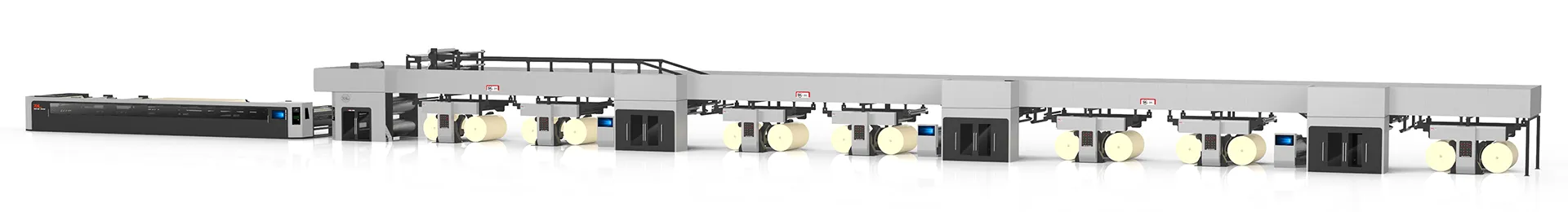

Corrugated Board Machinery

Corrugated board production lines are fully integrated systems used to manufacture corrugated board through a continuous process that combines fluting, gluing, bonding, drying, and cutting. These machines transform raw materials into structured sheets with a wavy internal layer, providing the strength and cushioning needed for packaging applications. Corrugated board is widely used in the production of cartons, trays, shipping containers, and other packaging formats due to its high compression resistance and durability during handling and transport. We offer corrugating lines for 2-ply, 3-ply, 5-ply, and 7-ply corrugated board, giving customers flexible options based on the required board strength, material usage, and application needs.

-

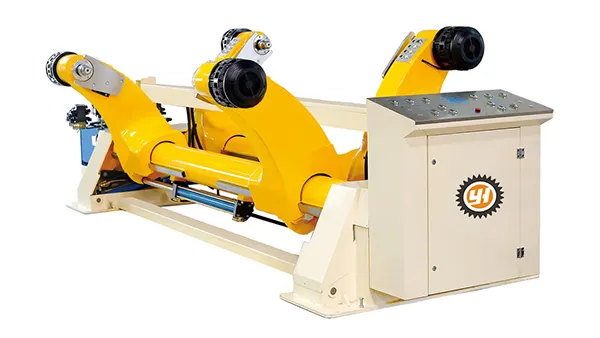

- Roll Stand Used in corrugated cardboard production line for holding and feeding paper rolls

-

- Single Facer Corrugator machine for making single-faced corrugated board consisted of a fluted medium adhered to a flat linerboard

-

- Automatic Splicer Applied in conjunction with corrugator roll stand to automatically join two paper rolls for continuous operation and enhanced productivity

-

- Pre-Heater Designed for preheating paper rolls to reach the desired process temperatures for optimal bonding of corrugated board

-

- Glue Machine Used in corrugated cardboard production line for uniform and precise adhesive application

-

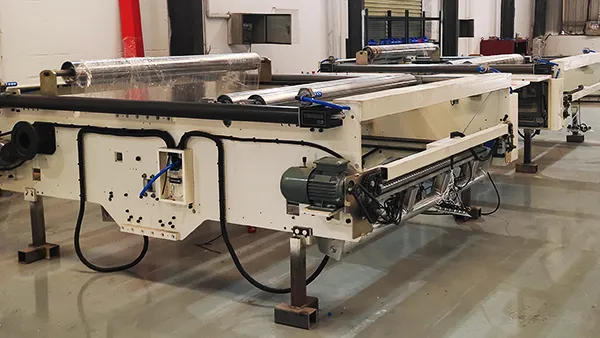

- Drive Roll Stand Adoption of up and down independent motor drive for stable and efficient operation of corrugated board production

-

- Double Facer (Double Backer) Designed for bonding single-faced corrugated board to another linerboard to form a double-faced corrugated board

-

- Corrugated Starch Adhesive Mixing System Added in corrugated starch glue preparation stage for making consistent starch adhesives for corrugators

-

- Corrugated Web Guiding & Tension Control Used for the alignment of single-faced corrugated board web with optimum tension control

-

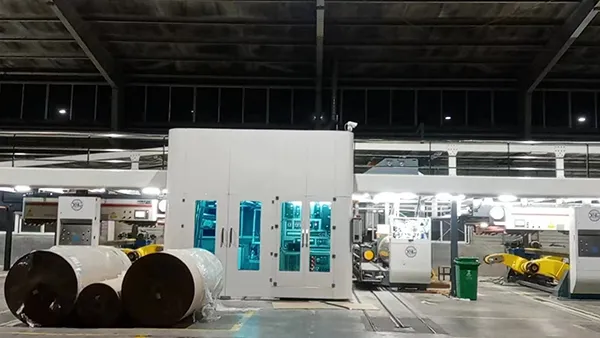

- Overhead Bridge Conveyor Used to store and transfer single-faced corrugated board for smooth transport of corrugated board

-

- Corrugated Board Printing and Converting System Inline converting line consisted of printing, slotting, die cutting and counting modules for the conversion of corrugated board

To meet different production requirements, our corrugated board machinery is available in multiple speed and width options:

- Production Speed Options

Our corrugating machines are available with maximum operating speeds of 150, 200, 250, 300, 400, and 450 meters per minute, allowing customers to choose the right setup for their capacity needs. - Working Width Range

Available widths include 1400 mm, 1600 mm, 1800 mm, 2000 mm, 2200 mm, 2500 mm, 2800 mm, 3100 mm, 3300 mm, and up to 3600 mm, supporting both standard and large format corrugated board production.

What types of packaging products can be made using a corrugated board production line?

Are single facer machines expensive to maintain?

What is the maximum mechanical speed of the flexo printing line?

We offer complete roll refurbishment and retrofit solutions tailored for the corrugated packaging and printing sectors. Our services cover a wide range of components, including corrugating rolls, pressure rolls, glue rolls, doctor rolls, and cassette units.

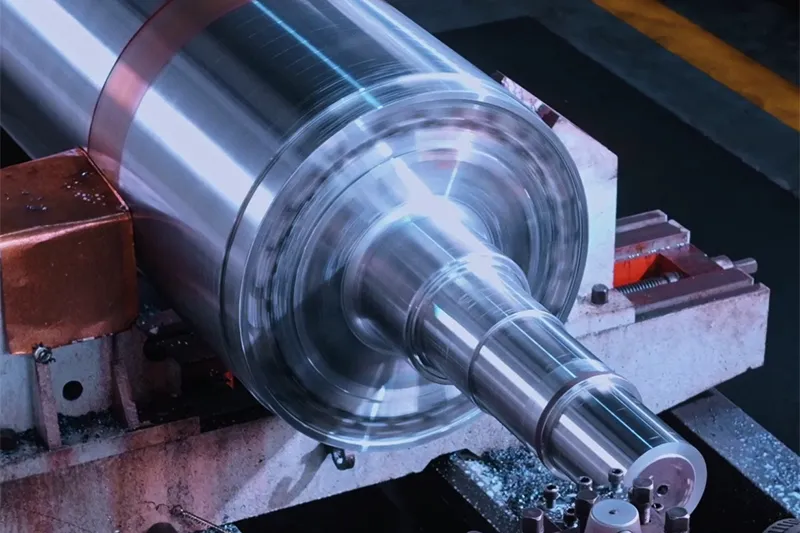

- Corrugating Roll Repair & Refurbishing Services

- Pressure Roll Repair & Refurbishing Services

- Glue Roll Repair & Refurbishing Services

- Doctor Roll Repair & Refurbishing Services

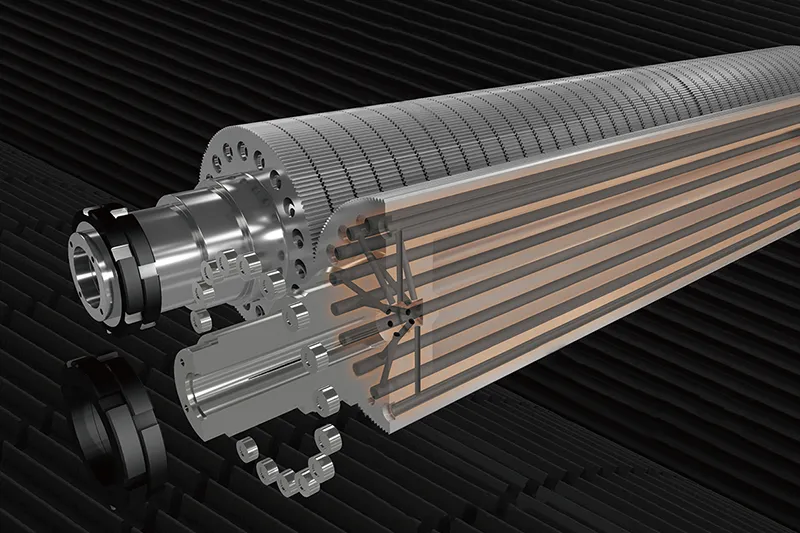

- Corrugator Cassette Repair & Refurbishing Services

We focus on delivering high-quality customized solutions for corrugator machine components, tailored to meet the unique needs of our customers in corrugator rolls and corrugated board equipment.

- We use high-quality 50CrMo forged alloy steel for the production of corrugating rolls, ensuring exceptional durability and a longer lifespan.

- Our computer-optimized flute profile design is key to achieving high-speed stability, enhanced performance, and cost control. By carefully analyzing customer needs, we customize the ideal flute design to deliver the best results and maximize profitability.

- With over 20 years of experience in corrugating roll design and manufacturing, our technology is recognized as an industry leader both locally and globally.