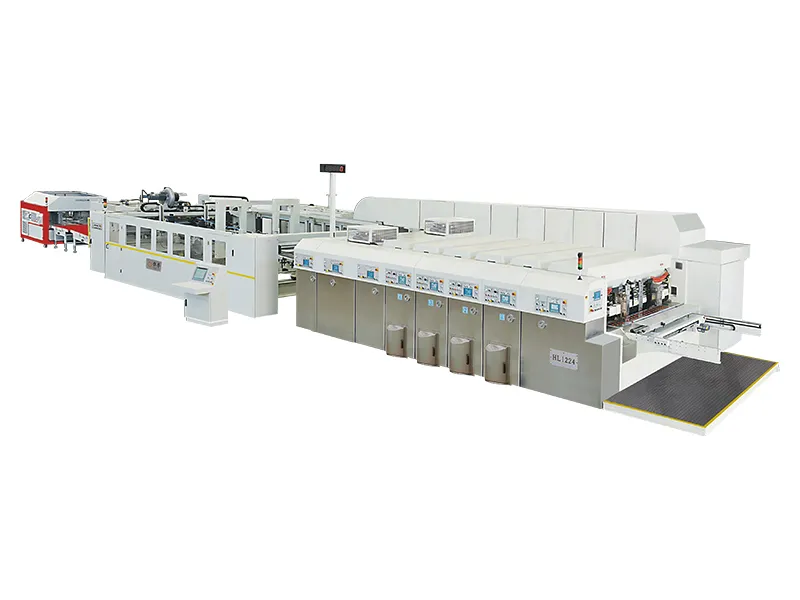

Corrugated Board Machinery

Corrugated Board Printing and Converting System

Inline converting line consisted of printing, slotting, die cutting and counting modules for the conversion of corrugated board

Corrugated Board Machinery

Corrugated Board Printing and Converting System

Inline converting line consisted of printing, slotting, die cutting and counting modules for the conversion of corrugated board

- Maximum mechanical speed: 300 pieces per minute

- Maximum printing area: 1540mm x 2800mm

- Maximum board thickness: 12mm

Our integrated corrugated board production line is designed to streamline every step in the manufacturing process. This cardboard conversion system combines printing, slotting, die cutting, gluing, and automatic packaging, enabling a smooth and efficient workflow from start to finish. With the addition of automated feeders, packaging machines, and robotic arms, the system reduces manual labor and optimizes the overall production speed. The seamless connection between printing, converting, and packaging stages ensures consistent quality and maximizes operational efficiency, meeting the high demands of modern corrugated board production.

| Model | 900×2000(2400) | 1200×2000(2400/2800) | 1400×2000(2400/2800/3000) | 1600×2800(3200/3600) |

| Max. machine speed (pcs/min) | 300 | 280 | 220 | 180 |

| Max. feeding size (mm) | 880×2000 | 1180×2000 | 1380×2000 | 1570×2800 |

| Min. feeding size (mm) | 300×650 | 350×750 | 420×750 | 450×850 |

| Max. printing area (mm) | 800×2000 | 1150×2000 | 1350×2000 | 1540×2800 |

| Skip feeding (mm) | 1100×2000 | 1500×2000 | 1700×2000 | 1900×2800 |

| Thickness of printing plate (mm) | 7.2 | 7.2 | 7.2 | 7.2 |

| Min. slotting space (reverse knife) (mm) | 240×80×240×80 | 250×90×250×90 | 250×90×250×90 | 280×100×280×100 |

| Max. slot depth (mm) | 250 | 320 | 320 | 560 |

| Max. thickness of board (mm) | 12 | 12 | 12 | 12 |

- Efficient dust removal ensures a cleaner environment, boosting overall performance.

- Vacuum adsorption printing delivers high-definition, precise results for superior printing quality.

- It can be equipped with hot air, infrared, or UV drying options, along with a doctor blade to further enhance printing quality.

- Full-coverage printing ensures even, dot-to-dot flexographic prints for consistent results.

- The independent PLC system with a touchscreen interface offers simple and intuitive control.

- Servo-driven die-cutting ensures high precision and accuracy in every cut.

- Remote maintenance functionality allows for quick troubleshooting, reducing downtime and improving efficiency.

- The lead edge feeding system enhances the airflow, ensuring smoother and more accurate paper feeding.

- Dust removal system, including brushes and fans, clears paper debris from the board surface and can be adjusted by board size segments.

- The gap between the roller and the paper board position, as well as the left and right edge alignment, are computer-controlled for precise adjustments.

- The main motor includes a start-up protection system, ensuring the feeder cannot start unless securely locked.

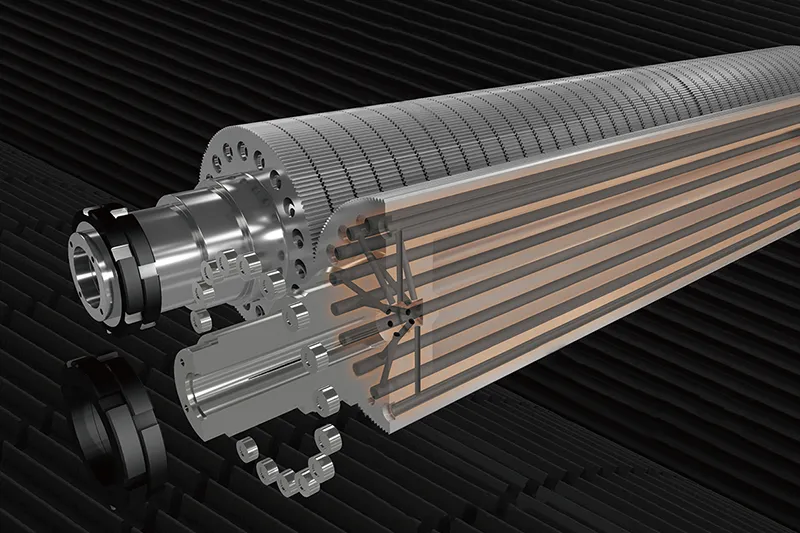

- The anilox roller is equipped with a pneumatic clutch, which synchronizes with the printing press when the unit is in operation. When the unit is not involved in printing, the anilox roller stops rotating, preventing damage to the rollers and ensuring independent cleaning without needing to match the printing press's speed.

- The anilox and doctor rollers are set with a fixed speed differential, allowing the doctor roller to effectively scrape off excess ink.

- The lateral phase is digitally controlled by computer, with a control range of ±10mm for precise adjustments.

- The automatic cleaning system ensures thorough ink recovery during cleaning.

- After cleaning the printing plate, the cleaning system automatically resets.

- Optional doctor blade ink system available, to ensure precise ink application during printing.

- Single-shaft dual-blade slotting ensures efficient cutting with box height adjustments made using an internal gear mechanism that avoids contamination from lubrication.

- The upper and lower knife holders are linked by a drive shaft, maintaining precise alignment during movement, which helps to extend the lifespan of the blades.

- Slotting phase and box clearance are controlled digitally, providing precise and consistent results throughout production.

- Pre-pressing wheels, crease wheels, and slotting knife holder positions can be fine-tuned through digital and electric controls, ensuring optimal performance and flexibility.

- Self-locking mechanisms are in place to adjust the gap between the slotting knife holders, offering stability and reliability.

- Similarly, the self-locking design is used for adjusting the gap between pre-pressing and creasing rollers, ensuring accurate and smooth operation.

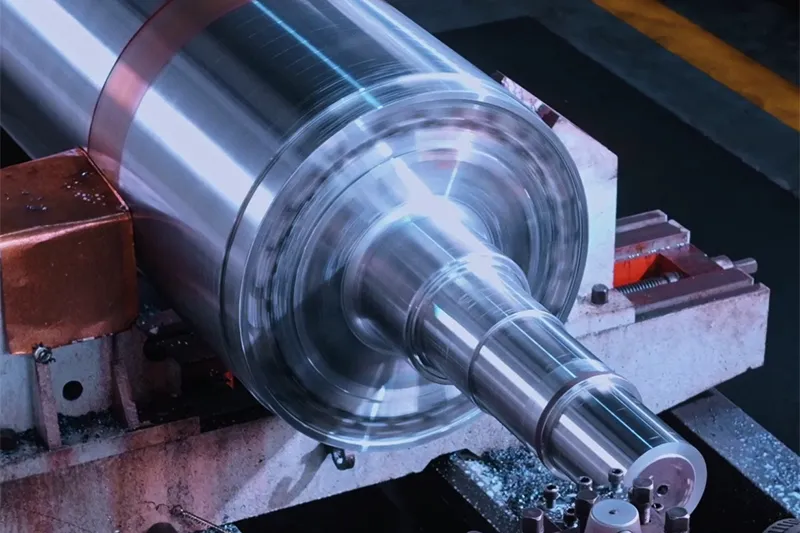

- The rubber roller features a mechanical spiral direction change with a 50mm floating lateral structure, providing smooth transitions during the cutting process and reducing wear.

- Lateral phase control is managed through a digital and electronic system, offering a precise adjustment range of ±10mm for enhanced accuracy in alignment.

- The conveyor rollers are designed with a self-locking structure for easy and stable adjustments, ensuring consistent material flow.

- The rubber roller compensation is driven by an independent motor, which adjusts the roller's speed with a compensation range of ±3mm, allowing for accurate alignment throughout the operation.

- A built-in leveling system ensures the anvil roller surface remains flat, improving cutting precision and delivering uniform results every time.

- The counter stacker is designed for high-speed, precise control of stack quantities, ensuring accurate stacking as per the set parameters.

- The pneumatic pusher extends based on the predetermined stack count, efficiently pushing the corrugated board stacks out for seamless processing.